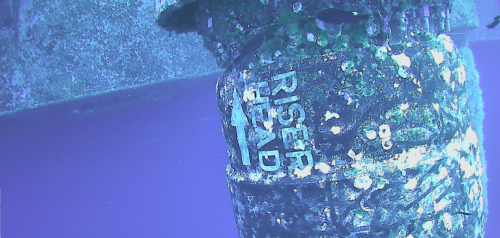

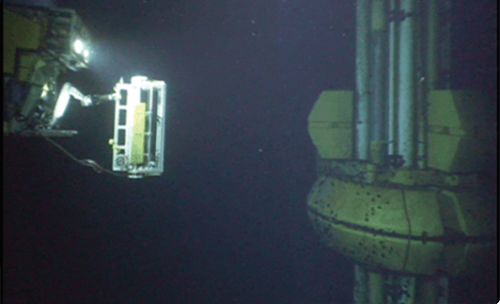

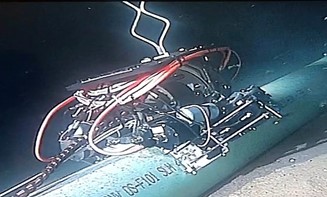

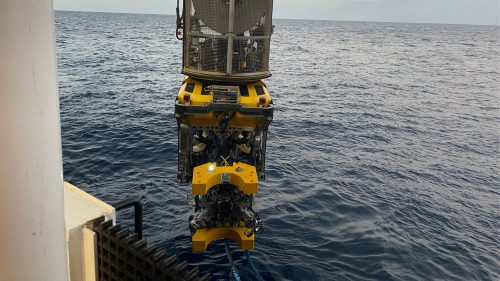

Flexible risers are susceptible to specific integrity challenges, particularly in harsh deepwater environments. The most common issues include mechanical damage to the outer sheath and failures in the venting system, which can lead to pressure breaches and flooding of the riser annulus. This flooding accelerates corrosion of the internal wires and significantly weakens the riser’s structural integrity. Studies show that approximately 35% of flexible risers experience such problems. The Fototerra–Sonomatic JV has extensive experience in identifying and mitigating these risks early—well before they impact operational life.